Underlayment: a crucial part of every roof system

Underlayment: a crucial part of every roof system

Do you agree that the roof is one of the most important parts of your house, especially as it protects you and your family from bad weather conditions? Let's have a look together to the underlayment shingle that IKO offers.

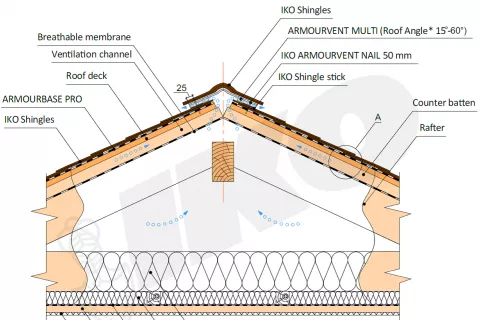

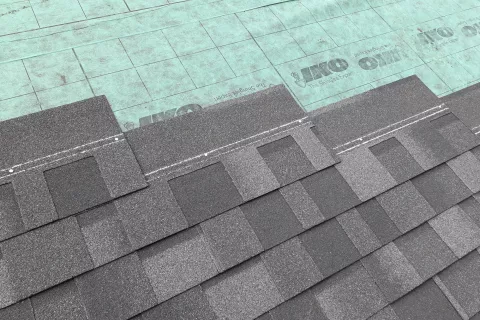

Take a look at the structure of a correctly installed shingle roof offering protection against all types of weather.

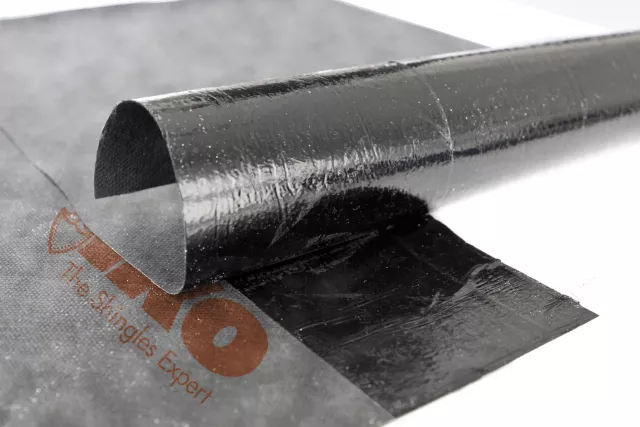

Shingles are not the only part offering protection, everything beneath them does as well. This invisible part is called the roof system. A key component of this roof system is the underlayment. The underlayment of a roof is a water resistant and waterproof membrane which is installed between the shingles and the wooden deck. As it is an extra layer of protection from severe weather conditions, the installation of an underlayment is mandatory. A shingle roof system without an underlayment is not covered by IKO warranty.

<<< Underlayment as part of the roof system

Types of underlayment

There are two basic types of underlayment used beneath roofing materials:

- Bituminous underlayment

- Non-bitumen synthetic underlayment

On the European market most synthetic underlays and breathable membranes are used as diffusion foils beneath wooden decks or wooden battens. They protect the insulation in case water would infiltrate through concrete or ceramic tiles. Diffusion foils cannot be penetrated with nails because the penetration between the membrane and the nail is not 100% watertight.

The big advantage of a bituminous underlayment is that every penetration by a nail is waterproofed. A bituminous underlayment is mostly used over wooden decks, especially under shingles or sometimes even under metal roofing as a safety hydro-insulation. We know many types of these underlays:

- reinforced with fibers or polyester

- finished with the sand or polypropylene

- self-adhesive or non-self-adhesive

IKO has a well-known range of products called Armourbase underlayments. All the IKO Armourbase underlayments are on a bituminous base, reinforced with polyester and finished with a polypropylene fabric. They are very light but at the same time also very strong and durable. The average weight of these rolls (30 m²) is only 9 kg, so the handling on a roof is very comfortable. The tear resistance of Armourbase underlayments is enormous, which means a roofer can feel safe, even on steeper slopes. The polypropylene fabric prevents slippery conditions and holds a firm contact with the wooden deck.

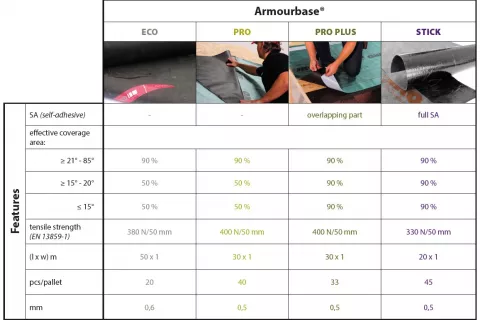

IKO has four types of underlayment in its range:

- Armourbase ECO

- Armourbase PRO

- Armourbase PRO PLUS

- Armourbase STICK

IKO Armourbase underlayment range

Armourbase ECO is an economic version of underlayment. One roll is 50 m². The polyester inlay is saturated with modified bitumen. The polypropylene finishing is black with a white IKO logo. This underlayment is suitable for bigger projects, with standard slopes where the investor wants to reduce some costs, without having to worry about quality loss.

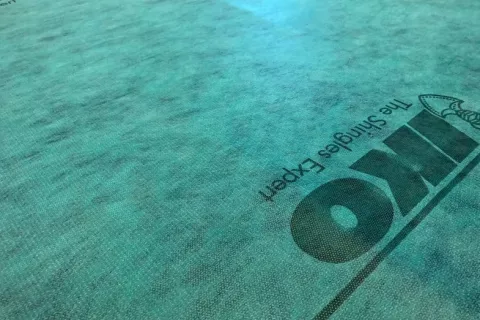

Armourbase PRO is the IKO flagship and is the most sellable underlayment. One roll contains 30 m². The Underlayment has a strong polyester inlay saturated with modified bitumen and the polypropylene fabric is green with a black IKO logo. Armourbase PRO is recommended for any residential project where the quality comes first.

Armourbase PRO PLUS is another modern underlayment with self-adhesive bituminous strips for the adhesion of the overlapping. One roll is 30m². The finishing polypropylene is a grey-purple color with horizontal and vertical lines (grid) and with a black IKO logo. These lines are very useful for a better alignment of the shingles. Because of the self-adhesive horizontal strips, the underlayment is recommended for roof projects with slopes less than 20 degrees.

Due to its fully self-adhesive characteristic, the Armourbase STICK is a very unique underlayment. One roll contains 20 m². The finishing on top is the grey polypropylene fabric with a red IKO logo. Under the release foil on the back side you will find very sticky modified bitumen. That is why this underlayment is recommended for very low slopes starting from 9,5 degrees up to vertical walls. This underlayment is an excellent solution for parts of roofs which are affected with ice dams or other critical roof parts.

Installation of underlayment and slope limitations

An underlayment should always be installed as flat as possible without any wrinkles, buckles or waves which can later be visible on the shingle surface. It is recommended to start applying the underlayment from the eaves and continue to upper parts of the roof. Drip edge flashing must be installed first and then the underlayment comes over the flashing. The underlayment must be glued on the drip edge flashing. Rake flashings on the gable part must always be installed on top of the underlayment. It is recommended to fix the underlayment with the standard IKO roofing nails.

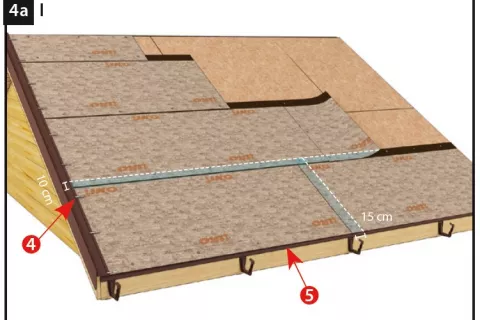

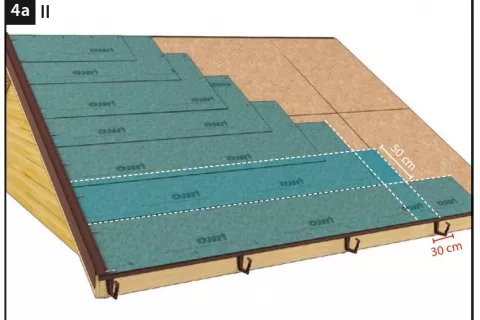

Slopes 9,5°- 20°

Option 1: it is advised to cover the entire roof deck with an IKO Armourbase Pro Plus or -Stick adhesive underlay or a similar modified base sheet which will seal the entire deck. Follow a 10 cm horizontal overlap for the consecutive rows while end laps must be 15 cm for the Armourbase Stick or 30 cm for the Armourbase Pro Plus and vertically sealed with IKO Shingle Stick.

Option 2: use an IKO Armourbase Pro or ECO underlay or a similar base sheet, to provide a double coverage of underlay to the roof deck. Cut a starter strip 50 cm wide and lay succeeding courses fastened with 50 cm horizontal laps and 30 cm end laps.

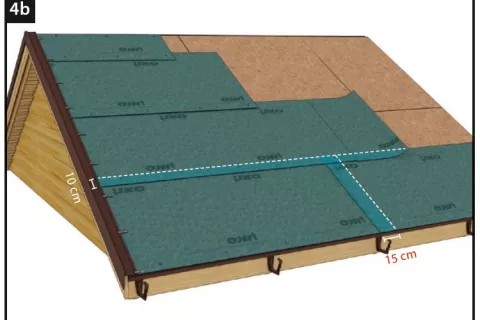

Slopes 21°- 85°

The entire roof deck should be covered with an IKO Armourbase underlay or an approved shingle underlay. The underlay should be installed parallel to the eaves with a min. 10 cm horizontal lap and 15 cm end laps. On IKO Armourbase Pro, - Pro Plus, - Stick and - ECO there are 10 cm lines on the rolls for easier overlapping. Secure the underlay with only enough nails to hold it in place.

Slopes 85°- 90°

No underlay required. Only self-adhesive shingles such as Cambridge Xtreme 9,5° or ArmourShield PLUS can be applied.

Underlayment failure

Some underlayments may fail for a number of reasons:

Poor quality

Poor quality underlayments absorb more water. Water absorption can cause wrinkling as the product expands. These wrinkles may telegraph through to the roof covering products, such as thinner bitumen shingles. Underlayment as felt paper is not recommended to apply over roof decking. Water and moisture from a wet underlayment may be absorbed by the roof deck, which can cause problems with expansion and contraction of the deck. The typical result of this failure is wrinkled shingles.

UV exposure and resistance of underlayment

Anywhere the underlayment is exposed directly to sunlight, UV radiation will accelerate its deterioration. Even though an underlayment can serve as a temporary, short-term roof cover, it’s necessary to install shingles over this underlayment within 2 or 3 weeks. UV radiation can make the polypropylene fabric peel off first; however the bitumen part will still be watertight. Anyhow aesthetically it doesn’t look good. So installing the shingles as soon as possible is highly recommended.

<<< Failure regarding of UV exposure

Remember:

The underlayment is a key component of the roofing system. The price difference between underlayment options usually adds up to a few hundred euros in your overall roof replacement project. If you are investing in high quality IKO shingles that will improve your home’s value for years to come, choosing a better quality, more durable, water-resistant underlayment is well worth the extra cost. That is why IKO the professional range of Armourbase underlayments is highly recommended.

Want to see the high quality of our Armourbase underlayments before making your decision? Or are you having difficulties deciding between two types of Armourbase?