Competitors test: IKO shingles vs. tested products – part 1

We believe that IKO’s expertise crushes quality of the products tested in the competitors test – part 1.

We often get the question: Why would we choose IKO? Why wouldn’t we go for a shingle manufactured by a Russian or American competitor? Our most important answer only contains one word: quality. The shingles IKO offers worldwide are made with years of knowledge and expertise. Of course talk is cheap, so we decided to prove our quality with some simple, yet important comparison tests.

Keep in mind that a proper application is one of the most critical aspects of a successful roofing project. Incorrect placement of nails is a leading cause of many problems on roofs, especially causing leaks and wind blowing off poorly installed shingles. Compared to the products in the competitors test, we believe that the manufacturing process of IKO’s laminated shingles (Cambridge) offers a better, more developed protection against these roofing problems.

In our opinion, the products tested in the competitors test don’t stand a chance on the following topics:

1. The size of the shingle

2. The width of the shim

3. Lamination and gluing system

4. Security of gluing

5. Nailing zone and angle cut.

Today we take a look at the size of the shingle, the width of the shim and the gluing system.

1. The size of the shingle

With a length of 1038 mm and a width of 349 mm the Cambridge Xpress and Cambridge Xtreme 9,5° shingle is the biggest shingle in this range. None of the products tested does better.

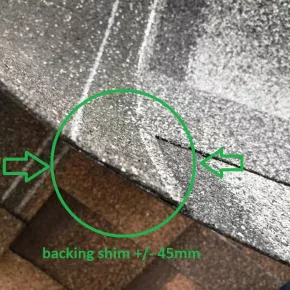

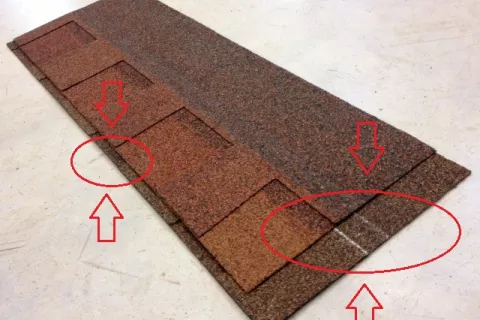

2. The width of the shim

Cambridge laminated shingles are produced with a nailing zone. Compared to laminated shingles from the products in the test, IKO’s nailing lane is up to 2-3 times larger. This makes sure that every nail comes through the two layers of wide shim, which means a correct nail placement. In our opinion, the smaller nailing areas of the products in the competitors test make it easy to poorly install the shingles.

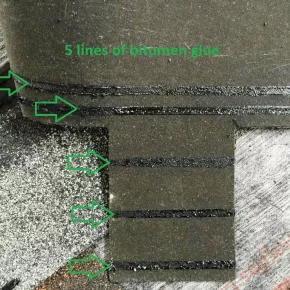

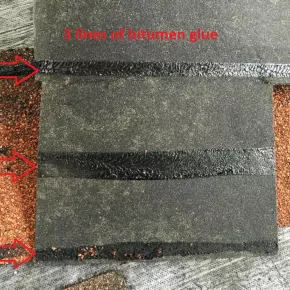

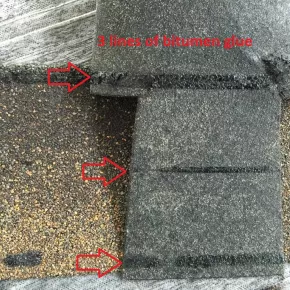

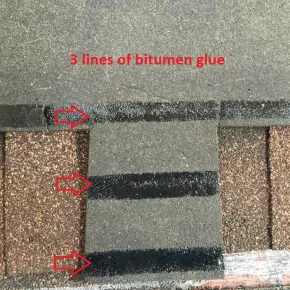

3. Lamination and gluing system

Laminated shingles are produced from two parts which are glued together with special modified bitumen. The products in the competitors test only use 3 lines, while the gluing together of IKO laminated shingles is done with five strips of bitumen. In our opinion, this makes IKO shingles the most developed option.

Be sure to check our blog posts frequently!

We’ll be posting the second part of the “IKO vs. competitor” test soon.

Or subscribe to our newsletter (see bottom of this webpage)

Contact us if you want to verify which products were included in the competitors test.