Search

Search

1361 results were found.

In the previous blog post we already gave you 4 tips and tricks for the application of roof shingles during hot weather. Today we are going to take a look at the other 4. Follow our tips and the installation of a new roof during the summer or in tropical regions will be easier as ever before!

- Storage of roof shingles

- Proper footwear

- Planning the roof installation

- Avoid footprints and scuffing from work

- Sponges to avoid sliding / burning

- Protect yourself

- Cool the shingle surface

- Wind-seal dots side up

5. Have a piece of sponge from an old sofa

It’s always good to have a square piece of sponge or yellow foam (e.g. 1mx1m/10cm thick) in your working truck. This sponge prevents that you slide down on steep roofs and avoids burning from roof shingles during the application.

Additional tip: have two pieces of sponge / foam. Use one to sit or knee down on and put some roof shingles on the second one.

6. Drink more water and use sunscreen during hot weather

You need more water when your body temperature rises. Keep hydrated when you're working on roofs in hot temperatures to stay healthy and attentive. When you're outside in the heat, it’s important to drink plenty of fluids to prevent dehydration. We need fluids to keep our bodies properly cooled. Without enough water, you can experience muscle cramping, a heat exhaustion or a heat stroke. Use sunscreen on roofs to avoid getting a burn during sunny days.

7. Garden hose and cold water to cool the shingle surface

If a repair or other rooftop work is required during hot sunny weather on existing shingled roofs, the shingles will be susceptible to scuffing and possible roof shingle damage. In such cases it is therefore often best to wait until cooler temperate conditions prevail before attempting roof shingle repair. The use of a garden hose and cold water to cool the shingle surface in very hot conditions is a technique that may facilitate the bond separation.

8. Wind-seal dots side up

Prior to their installation, roof shingle bundles will likely be lying in the sun for some time. When you remove shingles from a warm bundle, always spread these shingles on the roof with self-sealing dots side up. This way you make sure these shingles won’t stick on the existing roof or on already installed new roof shingles. It’s good to do the same thing with any scrap of roof shingle or left over.

With these tips you will be able to work well during hot temperatures and install a perfect new roof!

Good luck!

We believe that IKO’s expertise crushes quality of the products tested in the competitors test – part 1.

We often get the question: Why would we choose IKO? Why wouldn’t we go for a shingle manufactured by a Russian or American competitor? Our most important answer only contains one word: quality. The shingles IKO offers worldwide are made with years of knowledge and expertise. Of course talk is cheap, so we decided to prove our quality with some simple, yet important comparison tests.

Keep in mind that a proper application is one of the most critical aspects of a successful roofing project. Incorrect placement of nails is a leading cause of many problems on roofs, especially causing leaks and wind blowing off poorly installed shingles. Compared to the products in the competitors test, we believe that the manufacturing process of IKO’s laminated shingles (Cambridge) offers a better, more developed protection against these roofing problems.

In our opinion, the products tested in the competitors test don’t stand a chance on the following topics:

1. The size of the shingle

2. The width of the shim

3. Lamination and gluing system

4. Security of gluing

5. Nailing zone and angle cut.

Today we take a look at the size of the shingle, the width of the shim and the gluing system.

1. The size of the shingle

With a length of 1038 mm and a width of 349 mm the Cambridge Xpress and Cambridge Xtreme 9,5° shingle is the biggest shingle in this range. None of the products tested does better.

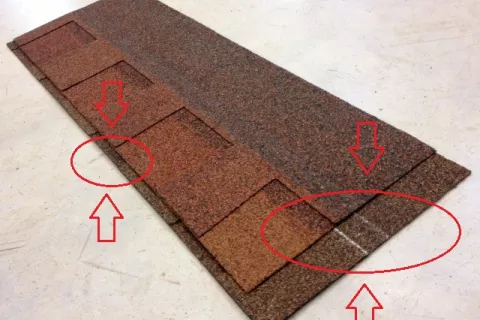

2. The width of the shim

Cambridge laminated shingles are produced with a nailing zone. Compared to laminated shingles from the products in the test, IKO’s nailing lane is up to 2-3 times larger. This makes sure that every nail comes through the two layers of wide shim, which means a correct nail placement. In our opinion, the smaller nailing areas of the products in the competitors test make it easy to poorly install the shingles.