Proper nailing is essential to the performance of roof shingles

Bitumen roof shingles may be one of the simplest roofing materials to install, but nevertheless they also require specialized and exact rules on how to be fastened. It is important to apply roofing nails in the right quantity and location to securely lock a shingle into its place. Accurate nailing affects the performance of roofing shingles and it is also required by the International Building Code.

Correct roofing nails

Roofing nails are used in roof installations to fasten shingles, to install the roofing underlayment for waterproofing and to attach roof tiles and sheet metal. There are different kinds of roofing nails, made of different materials and in various sizes.

A roofing nail should have a minimum nominal shank diameter of 12 gauge, 2,67 mm, and a minimum head diameter of 9,5 mm. Roofing nail should have a barbed shank until the head which eliminates nail pops, blow offs and roof leaks. A large nail head and heavier shank gauge provide greater holding power. All nails must be corrosion resistant; for example galvanized by various processes, aluminium, copper or stainless steel.

Nail length

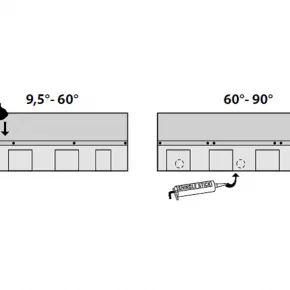

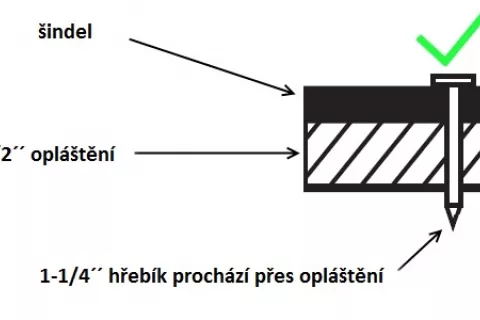

Roofing nails should be long enough to penetrate the roofing material and go 19 mm into OSB, solid wood, plywood or non-veneer wood decking, or through thickness of decking, whichever is less. To determine the nail length, you should consider the number of layers of shingles, shingle thicknesses, underlayment and flashings (installed on eaves, sidewalls and valleys, etc.).

Some situations allow nails with less penetration above exposed soffits if extra nails are used. It is typical for garden houses, sheds or exposed soffits where the thickness of sheathing boards is 18-20mm. Check the local building codes and regulations.

These 2 pictures show inadequate penetration of the wooden deck.

The correct penetration of the wooden roof deck looks like this.

The correct penetration of the wooden roof deck looks like this.

The correct penetration of the wooden roof deck looks like this.

We have to use 30 mm long nails if we are installing thicker shingles like the laminated shingles Cambridge Xpress or Cambridge Xtreme 9,5°. For reroofing (shingle over shingle) or hip and ridge application it is necessary to use minimum 35 mm long roofing nails.

General fastening rules

Proper fastening is essential to a good roof performance. To ensure proper nailing during the shingle application:

- Use the correct type, size and grade of nail as is specified in the application instruction.

- Use corrosion resistant nails.

- Use the recommended number of nails per shingle.

- Position the nails according to the shingle specifications.

- Align the shingles properly before nailing to avoid exposing nails in the course below

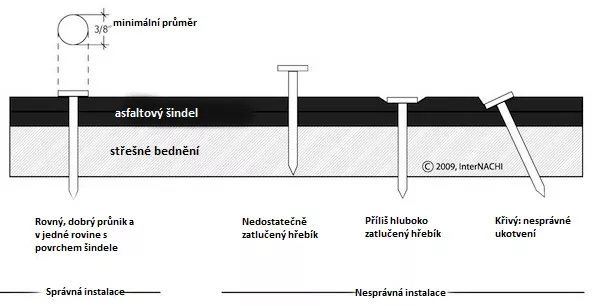

- Drive the nails straight and flat with the shingle surface.

- Do not break the shingle surface with the nail head.

- Do not drive nails into knotholes or cracks in the roof deck.

- Repair incorrect nailing immediately.

- Always nail the shingle from one side to the other, so the shingle stays flat on the roof.

- Follow the application instructions concerning special nailing procedures for steep slopes, high wind areas, and any special requirements.

- Comply with local building codes.

If a nail does not penetrate the deck properly and cannot be tapped down to be properly driven, remove the nail, repair the hole in the shingle with bituminous mastic and place another nail nearby. If necessary, replace the entire shingle.

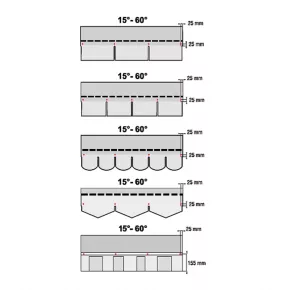

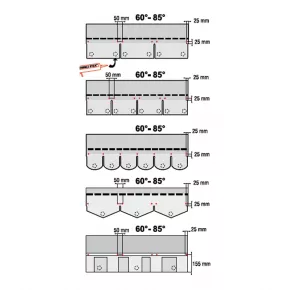

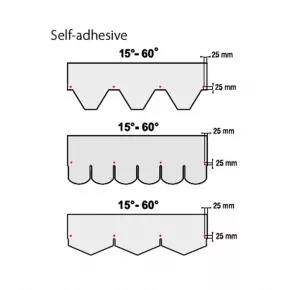

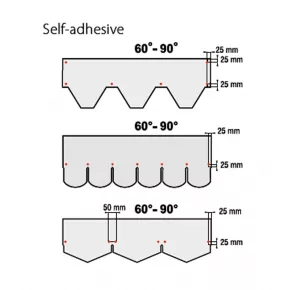

Nailing method and correct location of nails

Take a look at the different nailing locations on the different types of shingles.

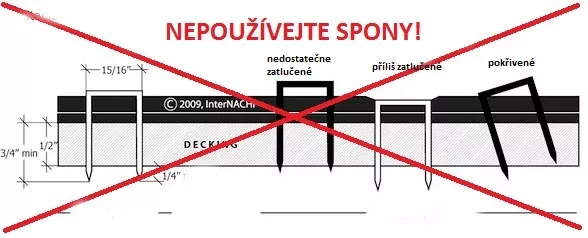

Improper shingle nailing

One of the most common defects with asphalt shingles is improper nailing. IKO and other manufacturers of asphalt shingles give specific instructions on how to fasten shingles, and they’re all pretty much the same. Unfortunately, some roofers don’t seem to pay a lot of attention to these instructions. That is why we want to highlight the two most common nailing defects with shingles: overdriven nails and improperly located nails.

Overdriven nails

Many roofers use pneumatic nail guns to nail down the shingles. When the pressure is set too high, the nails simply get driven into the shingles too far. When the nails are overdriven, the heads of the nails punch right through the mat of the shingle. This voids the shingle manufacturer’s warranty and greatly increases the potential for shingles to come loose and be blown off, possibly in full shingle sheets.

Improperly located nails

The other common nailing defect is improperly located nails. It is very problematic to have nails located too high on the shingle. The correct nail must be applied 2,5 cm above the cut-out and 2,5 cm from each edge. For the Cambridge shingle nails must be applied into the nailing zone. When properly placed, the nail will actually catch the top edge of the shingle below it. When the nails are located too high on the shingle, they never catch the shingle below. With this application mistake shingles are less wind resistant and easily can blow off from the roof.

Take a look at the examples of improperly located nails in this gallery.

Remember: Only properly driven and applied roofing nails are utilized as a preferred fixing system for asphalt roof shingles!