Search

Search

1361 results were found.

Take the following measures to help prevent ice dam problems:

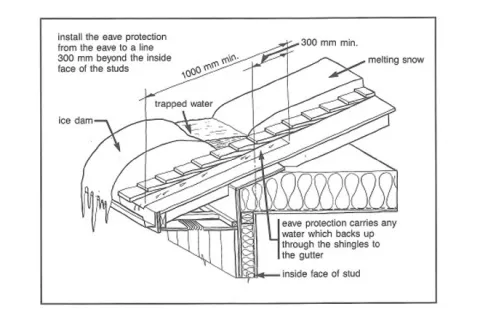

- Provide eave protection, and impervious IKO Armourbase Stick underlayment, at eaves and in the valley intersections, to stop water from penetrating through the shingles because of ice damming (see drawing). Armourbase Stick has good waterproofing properties: it is W1 ranked and has average values of 4 m in the water column test. Thanks to the bituminous compound, the underlay can enhance its waterproofing behavior and form an excellent prevention against ice damming.

- If the roof is insulated between the rafters, don't forget the ventilation gap above the rafters, which is created by the contra-batten, and sufficient intakes at the eaves.

- With a cold roof system, keep the attic space cold by insulating it from the warm house interior. This will reduce or eliminate snow melting.

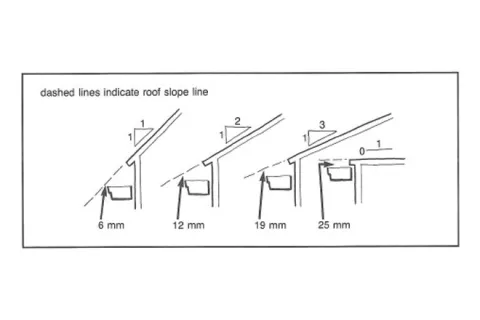

- In case there are no snow stoppers mounted on the roof and the snow slides freely and falls from the roof, ensure that the outer edge of the gutters is lower than the slope line to allow snow and ice to slide clear (see drawing). It must always be safe, to avoid danger for passers-by.

Place gutters below the slope line to allow snow and ice to glide clear. >>>

Following these guidelines will help you reduce the risk of roof problems. More roof problems such as typical roof failures and flashing problems will follow in the next blog. Stay tuned!

Interested in the products mentioned in this blogpost?

Distributor locator: Are you looking for a distributor?

Distributor locator:

Contact us to obtain the IKO distributors information in your neighbourhood.

Thank you for your interest in our newsletter! We have well received your subscription.

Get to know our products: see our shingles or accessories overview.

Get to know IKO, the Shingles Expert.

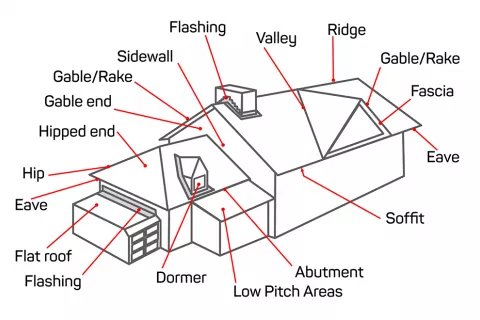

Rain and water is one of the major weather factors that continually threaten down your roof and invade your house in the form of a roof leak. Roof flashing is as important in preventing roof leaks as are the shingles themselves. The roof flashing is a thin metal, usually painted, galvanized or can be made from copper, aluminum etc. But not all flashing is the same. There are several different types of flashing which can be used close to many details on the roof.

Flashings: eaves, rakes, walls, chimneys, etc.

All areas on the roof surface where roof planes intersect or protrude through the roof surface (chimneys, vent stacks, dormers, walls, etc.) require flashings. Flashing is the construction procedure which is necessary to make these areas waterproof. Metal flashings are effective, because when properly installed, they can help accommodate roof, chimney, wall, or structural movements due to settlement, expansion, and contraction. Roof flashing drains water and is constructed in a system to work with the effect of gravity. When designed and installed correctly, flashings can only be defeated by water running upward. This can happen in the presence of snow, ice or wind-driven rain.

Flashings installation

Drip edge flashing on eaves and rakes

Drip edge is the simplest flashing. It is used at the rakes and eaves. It provides efficient water shedding and protects the underlying wood from rotting. The drip edge should be made of a corrosion-resistant material that extends back at least 8 cm from the roof edge and bends downward over the fascia/roof boarding. Apply the drip edge underneath the underlayment along the eaves to allow water to shed smoothly off the roof if it gets under the shingles.

The rake flashing is installed on top of the underlayment to prevent wind-driven rain from getting beneath it.