Search

Search

1361 results were found.

Improper shingle nailing

One of the most common defects with asphalt shingles is improper nailing. IKO and other manufacturers of asphalt shingles give specific instructions on how to fasten shingles, and they’re all pretty much the same. Unfortunately, some roofers don’t seem to pay a lot of attention to these instructions. That is why we want to highlight the two most common nailing defects with shingles: overdriven nails and improperly located nails.

Overdriven nails

Many roofers use pneumatic nail guns to nail down the shingles. When the pressure is set too high, the nails simply get driven into the shingles too far. When the nails are overdriven, the heads of the nails punch right through the mat of the shingle. This voids the shingle manufacturer’s warranty and greatly increases the potential for shingles to come loose and be blown off, possibly in full shingle sheets.

Improperly located nails

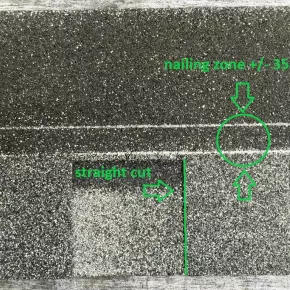

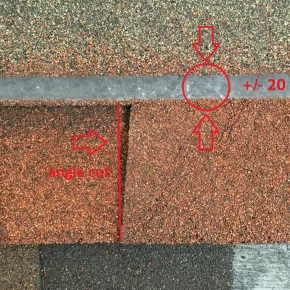

The other common nailing defect is improperly located nails. It is very problematic to have nails located too high on the shingle. The correct nail must be applied 2,5 cm above the cut-out and 2,5 cm from each edge. For the Cambridge shingle nails must be applied into the nailing zone. When properly placed, the nail will actually catch the top edge of the shingle below it. When the nails are located too high on the shingle, they never catch the shingle below. With this application mistake shingles are less wind resistant and easily can blow off from the roof.

Take a look at the examples of improperly located nails in this gallery.

Remember: Only properly driven and applied roofing nails are utilized as a preferred fixing system for asphalt roof shingles!

Interested in the product mentioned in this blogpost?

In our opinion, IKO’s expertise crushes quality of the products in the competitors test – part 2

At our earlier post we already proved 3 important advantages of IKO’s Cambridge shingle compared to the products in the competitors test:

- The size of the shingles: IKO’s Cambridge is the biggest shingle in the range vs. tested products

- The width of the shim: IKO’s nailing lane is up to 2-3 times larger (making correct nail placement easier) vs. tested products

- The gluing system: IKO laminated shingles are glued together with five strips of bitumen

Today we take a look at the other reasons why we believe, you should choose IKO’s quality: the security of gluing system and nailing zone + angle cut.

4. Security of gluing

The quality of the seal system holds shingles in place during high winds and protects your roof against wind-driven rain entering beneath the shingles. IKO Cambridge shingles are manufactured with a double line of defense in its critical shim area. Laminated shingles of the tested products only have one single line of glue in this critical part.

5. Nailing zone and angle cut

The Cambridge nailing lane is a clearly marked area of 35 and/or 45 mm for “Xpress” application and is the widest zone for accurate nailing. The straight cut of the “dragon tooth” part is in our professional view better for the shingle alignment compared to angle cut. When the products in the competitors test offer a smaller nailing zone, they do not combine it with a straight cut. We believe, yet another advantage of IKO’s laminated shingles.