Search

Search

1361 results were found.

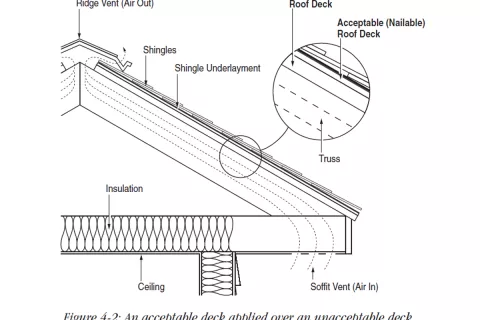

Unacceptable decks

- Cementitious wood fiber

- Gypsum plank

- Lightweight concrete

- Insulation boards

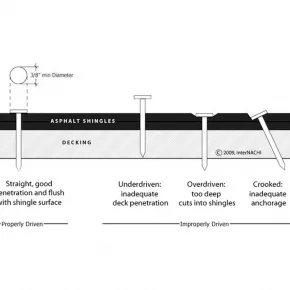

These materials are not acceptable as a roof deck for direct application of IKO shingles. These products are not likely to provide a proper surface for nails to hold the bitumen shingles. Direct shingle application can lead to over-driven or under-driven nails. Over-driven fasteners can damage the shingle, increasing the chance of wind blow-off and leakage due to wind driven-rain or ice-dam backup.

The heads of under-driven nails, or of those that back out, may prevent shingles from sealing, reduce the wind blow-off resistance, and puncture the shingle tabs above, leading to leaks.

These roof surfaces must be covered with an acceptable decking material, with ventilation as required, prior to the application of IKO shingles.

In the past, many shingle manufacturers didn’t recommend the use of nail guns when installing a new shingle roof. In that time, hand nailing was more popular. Most of them preferred an application with a shingle hatchet. Recently things have changed and a lot of roofing contractors started using different power tools, including nail guns.

Their main reason to use nail guns is to save time. A second reason is to facilitate the roofer’s job by reducing the manual work. Shingle producers also introduced special designed shingles with zones for accurate nailing. IKO offers two different laminated shingles, Cambridge Xpress and Cambridge Xtreme 9,5°, produced with nailing lanes for the fastening with a nail gun.

But the main question is: what is better, hand nailing or nailing with a nail gun? While many roofers have strong feelings one way or the other, the only thing that really matters is a shingle roof installed with the highest quality. Both methods of application have their own strengths and weaknesses, let’s compare. But first..

The importance of nail placement

The placement of each roofing nail will eventually determine the durability of roof shingles. Shingles are designed to be nailed on a specific location and the nail must be driven to a certain depth. Usually the nailing location is situated ± 25 mm above the cut-out and 25 mm from the end. However, on our laminated Cambridge shingles the position of the nails is between the two white lines which we also call the nailing lane or zone.

Every roofing nail must penetrate the wooden deck with a minimum of 19 mm. If this position or depth of the nail is off by even a little, water might penetrate inside or the shingle may be blown off in high winds. IKO’s manufacturing warranty coverage might also be voided if the inspection finds that the reason of the problem was incorrect nail placement.

For more tips on proper nailing, take a look at this blog.

Pros and cons of manual nailing

Supporters believe that hand nailing shingles gives them more control over the fastening process. They can use a certain “feeling” to determinate if the nail is deep enough and applied on the right location. Especially when working on a roof deck made of wooden planks this “feeling” can be useful. Wooden plank deck sheathing can contain many gaps, which the roofing nail can accidentally be driven into. The roofer working with a hammer can feel this and can quickly repair it with a second nail aside and glue the loose nail with a little bit of mastic.

Hand nail installers are quick to feel a nail miss in the wooden deck while nail gun operators have to rely more on sounds and intuition. Hand nailing might take a bit more time but there is the chance to correct mistakes on the spot. Due to the slower installation, labor costs will be higher. The material however will be lower, because shingle hatchet or hammer is cheaper than a nail gun.

Pros and cons of nailing with a nail gun

Roofing contractors who use a nail gun often believe that this pneumatic tool provides the same level of precision as hand nailing a shingle. But it’s important for the roofers to always test their tools before using them.

Over-pressured or under-pressured nail guns can cause over-driven nails. This brings potential risk and damage to your shingle roof. Nails that are applied too deep can cut the fiber-mat inside of the shingle, which can reduce their resistance to withstand high winds. In some cases shingles can even slide down the roof. Under-driven nails are too high and can cause a lift up of the shingle above, which might result in blow offs or cuts through the upper shingle.

The positive side is that roofers who are using nail guns can complete the whole project much faster, resulting in a lower cost for the homeowner. However there is a higher cost for the investment in power tools. A nail gun is a tool that has a magazine or tray that stores coiled roofing nails. One by one these fasteners are driven through the bituminous roof shingle and into the roof deck by a supply of air.

There is also another type of nail gun on the market where the power is supplied by gas fuel and ignition from the battery. The compressor needs to have a continuous supply of air pressure from 90 – 120 PSI. It all depends of the type of gun, the roof shingle used, the thickness of the roof deck and the outside temperature of installation. The set of tools, nail gun and compressor will bring the roofer more benefits in the long term. IKO has a very close cooperation with Stanley Black & Decker and during our Roadshows we deliver product demonstrations for Bostitch and DeWalt roofing nail guns.