Zoeken

Search

971 results were found.

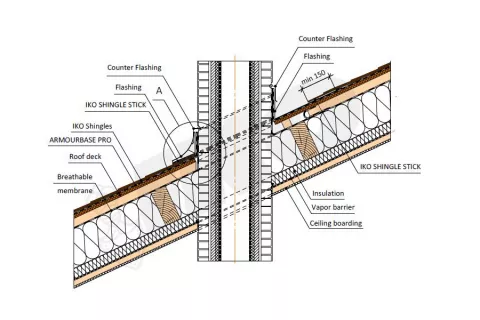

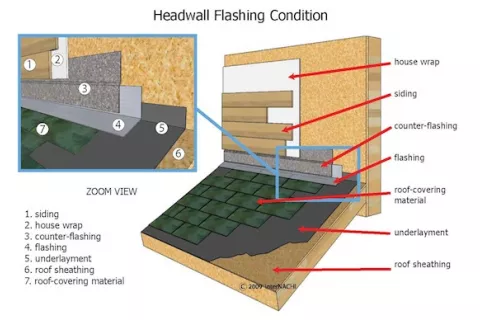

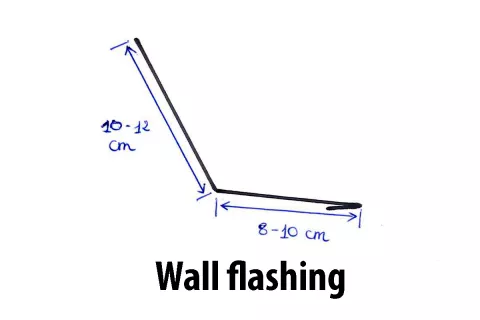

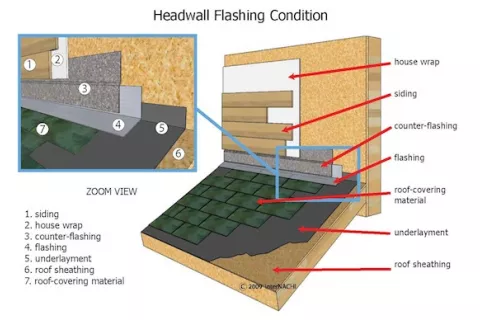

Flashing against vertical front wall

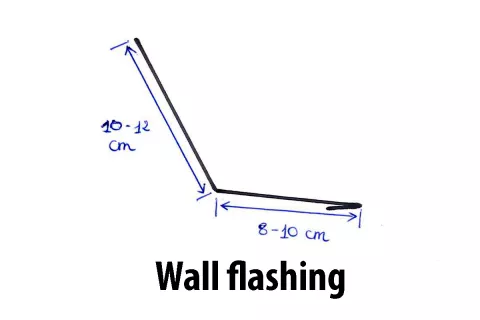

Apply shingles up the roof until a course must be trimmed to fit the base of the vertical wall. By planning you can slightly adjust the expansion in the previous courses, so that the last row is about 15-20 cm wide. Apply a continuous piece of metal flashing over the last course of shingles by embedding it with bituminous mastic and nailing it to the roof. Do not nail the strip to the wall. The metal flashing strip should be bended to extend about 10 cm up the vertical wall and 10 cm onto the last shingle course. Applying an additional row of shingles over the wall flashing strip on the shingle surface is optional. The last pieces of shingles must be fastened with face nails sealed over with a small dab of roofing cement. The top part of wall flashing can be placed under the siding or covered by a counter flashing (stucco wall).

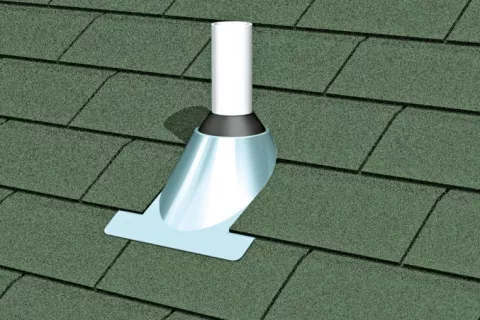

Soil stacks and vent pipes

Normally homes have circular vent pipes or ventilators projecting through the roof. Before installing the flashing or roofing accessory, bring the shingles up to the vent pipe. Then cut a hole in the shingle that will go over the vent pipe and set it in bituminous mastic. Be sure the flange or vent is positioned squarely on the roof. Avoid excessive use of mastic because it may cause blistering.

After the flashing is in place, continue applying the shingles. Cut the shingles in their successive courses to fit around the pipe and seal them with bituminous mastic where they overlap the flashing flange. The lower part of flashing is overlapping the lower shingles, and the sides and upper shingles are overlapping the flange. Remember, do not nail close to the pipe. Follow the same procedure where a ventilator or exhaust stack is located.

Flashings around chimneys

Because chimneys are usually built on an independent foundation that is separated from the main house foundation, the chimney can move independently of the rest of the house. To allow for chimneys and deck movement, the base flashing is secured to the roof deck and counter or cap flashing is secured to the chimney. When movement occurs, the base flashing and counter flashing will act as a movable joint. For chimneys projecting through the roof surface which are greater than 76 cm, we recommend placing a cricket behind the chimney. The cricket, sometimes called a wooden saddle, consists of two triangular sections of decking material (plywood, OSB, wooden boards) joined to form a level ridge that extend from the centerline of the chimney back to the roof deck. A cricket prevents the build-up of ice and snow at the rear of the chimney and diverts water runoff around the chimney. It also prevents water from ponding and backing up under the shingles during winter freeze or thaw periods. All roofing materials from the underlayment to the roofing shingles are applied over it.

Apply shingles up to the front edge of the chimney section. Then apply the front flashing against the front wall of the chimney. Bend the front flashing so that the lower section extends about 10 cm over the shingles and the upper section extends at least 10 cm up to the front wall of the chimney. Secure the overlaps with plastic roof cement. Use metal step flashings for the sides of the chimney, positioning the pieces in the same manner for a vertical sidewall. Secure each step flashing with bituminous mastic and nails to the wooden deck. Layer the end shingles in each course that overlaps the flashing in asphalt roof cement.

Instead of step flashing you can also install a single continuous metal flashing, which is folded together with the front and back part of the metal flashing. Be sure to turn up a hem on the horizontal roof side and secure the flashing with metal cleats. Do not nail the end shingles in each course through the metal flashing. Secure every ending shingle with bituminous mastic to the hemmed edge of flashing.

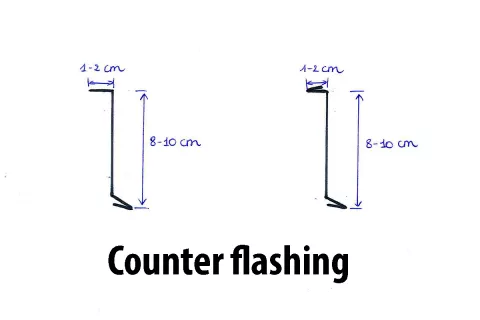

Counter and cap flashings

Counter flashing or cap flashing techniques will vary with the type of chimney finish, such as stucco, brick or stone. To keep water out of the chimney joint, begin by setting the counter metal flashing, typically copper, aluminum, or galvanized, into the brickwork or stucco. This is done by cutting out of a mortar joint to a depth of 2-4 cm and inserting the bent edge of the flashing into the cleared joint. Use one continuous piece of cap flashing for the front and one for the back part of the chimney. On the sides of the chimney, use several pieces of similar-sized flashing, trimming each piece to fit the particular location of brick joint and roof pitch. Start the side units at the lowest point and overlap each at least 7 cm side-to-side. This is a typical staggered (stepped) counter flashing for chimney or wall with mortar joints. Refill the joint when the cap flashing is installed with cement mortar, silicone caulk, or use a metal wedge and polyurethane sealant.

The continuous counter flashing technique uses a continuous metal piece instead of stepped counter flashing along the side of a chimney. It is an alternative to stepped counter flashings, which can lead to water leaks along the vertical joints in high wind or fine-grained snow.