Search

Search

1361 results were found.

Download here the product overview of our complete range of roof shingles and accessories season 2024.

↓↓ Interested to buy IKO Roof Shingles? - Contact us and find out your nearest IKO Distributor.

The shingles expert

About IKO:

IKO has become over time the shingles expert, which guarantees you the highest level of quality and reliability for your roof.

The company can benefit from the vertical integration of the IKO group: carefully and expertly self produced raw materials ensure a consistent and top quality in terms of end product.

IKO is the only European manufacturer that can rely on know how and technological advances specifically developed within the other IKO group shingles plants in Canada and in the USA, home countries of shingles.

Guarantee system

IKO also offers you a further sign of quality by having ALL its shingles CE marked.

This state of the art quality allows us to grant you a unique Shingles Platinum® guarantee system, which does not only cover the full cost (installation, transport, ...) of the product but which is based on a non digressive value.

Always nearby

IKO is also close to you, wherever you are; we have developed our local presence through a network of our own local companies or through strong local partners.

Design options

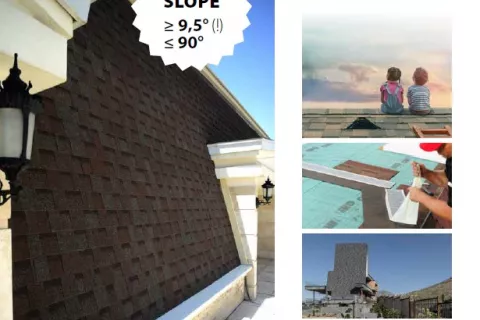

IKO offers you such a wide range of shapes and colors that you can choose a product at any time that will either match with your local traditional roof style, or that will stand out thanks to its originality.

We are constantly looking for new talent to strengthen our teams.

Are you interested to learn what it is like to work in one of the many locations of the European Division in IKO?

If you are a roofer, don't miss any of our updates!

Get the latest content and keep in touch with us through our newsletter!

↓↓ Download Cambridge Xtreme 9.5° Leaflet - check out your benefits with this exceptional and innovative roof shingle for the future.

How are roof shingles made?

Shingles are made in a continuous process:

- Large rolls of glass mat are fed into a dry looper, which serves as an accumulator.

The glass mat moves to the coater.

- At the coater, coating bitumen is applied to the top and bottom surfaces of the sheet.

Mineral stabilizers are added to the coating that improves the shingle's fire resistance and weathering characteristics.

- Next, granules are applied to the top surface of coating. Granules are ceramically coloured crushed rock;

the granules give the shingle its colour, but more importantly protect the coating from ultraviolet light.

4. Anti-block surfacing is then applied to the back of the sheet to prevent it from sticking to the machine and to other shingles when packaged.

A plastic tape is also applied to the back of the sheet to prevent the sealing strips from sticking to the next shingle in the package.

5. The granules are then pressed into the topcoating.

6. Once the sheet is cooled, sealing strips are applied. The sealing strips allow one shingle to bond to the overlying shingle on a roof and thus prevent wind uplift.

7. The roofing sheet is then measured and cut into shingles.

8. The shingles are wrapped into bundles and stored in the warehouse until they are ready to be shipped to the appropriate location.

Are you a professional and interested to see the production process with your own eyes? Contact us today for a plant visit.